|

||

|

|

||

|

|

||

|

|

#101 | |

|

Give to Learn

Freelander 2 Join Date: Aug 2010

Location: West Midlands

Posts: 18,717

Thanks: 1,155

Thanked 6,407 Times in 3,874 Posts

|

Quote:

I will also keep everyone notified of how the compensator works out  1 1 2 2My man also wanted to weld here marked with an arrow saying it would still swivel as there is movement for the cables ? i my self am not so sure.therefore i said i would wait and see how this one performed first.  3 3

__________________

Arctic Givology Learn to Give Everything is Achievable  ad altiora tendo. Check out our Nano meet dates http://www.midlandsnanomeets.co.uk/ http://www.the75andztclub.co.uk/index.php?thepage=howto " You do the work , we supply the expertise " Last edited by Arctic; 2nd July 2013 at 17:21.. |

|

|

|

|

|

|

#102 |

|

Loves to post

Rover 75 1.8T SE Join Date: Apr 2011

Location: Southport

Posts: 402

Thanks: 1

Thanked 72 Times in 37 Posts

|

I would still love to see an unmodified one of these all mounted up on a jig so it could be studied properly - either there is something very subtle about the design I'm not appreciating or its a wierd solution to the problem! Cant help feeling its been deliberately designed to be a bit "loose" which if you weld the wrong areas will rob it of its original design feature. mmmmmm

|

|

|

|

|

|

#103 | |

|

Passed Away

rover 75 saloon Join Date: Feb 2008

Location: leeds

Posts: 186

Thanks: 0

Thanked 0 Times in 0 Posts

|

Quote:

Don't weld the parts you have marked in your last photo. Your method will do the job, so long as the part holding the two cables can still swivel and not foul the bent bar. The offer made by Harry is intended for members who are not very handy or have the equipment. Its the best method for repairing one which has stretched and returns the bracket to its normal size, with the addition of the welded bar to prevent it going again. All for the price of the postage. Should any one have a new one, the same mod. can be done the same way, contact Harry and I am sure he will oblige. |

|

|

|

|

|

|

#104 |

|

Avid contributor

Rover 75 Conn Tourer CDTi Join Date: Nov 2008

Location: Elland.

Posts: 151

Thanks: 0

Thanked 1 Time in 1 Post

|

The chap doing my testing is well aware that some cars have H/B problems. His opinion is that no matter how high the lever or number of clicks, if it holds the car then it passes. Surely the object of the exercise.

Curiously my 1961 Rover 100 always had this problem too, in this case it was always the true "right angle" principle of the cables across the rear axle. Any variation and the cables never exerted the proper effort. Barnowlnoddy |

|

|

|

|

|

#105 | |

|

This is my second home

75 Contemporary SE Mk II 2004 Man. Sal. CDTi 135ps, FBH on red diesel, WinCE6 DD Join Date: May 2010

Location: Leeds

Posts: 17,273

Thanks: 2,160

Thanked 2,061 Times in 1,586 Posts

|

Quote:

That's not a bad bit of welding your man has done BTW  As already said, if you want an old one refurbed and modified or a new one modified, you only need to ask me.

__________________

Harry How To's and items I offer for free, or just to cover the cost of my expenses... http://www.the75andztclub.co.uk/foru...40#post1764540 Fix a poor handbrake; DIY ABS diagnostic unit; Loan of the spanner needed to change the CDT belts; free OBD diagnostics +MAF; Correct Bosch MAF cheap; DVB-T install in an ex-hi-line system; DD install with a HK amp; FBH servicing. I've taken a vow of poverty. To annoy me, send money. |

|

|

|

|

|

|

#106 | |

|

This is my second home

75 Contemporary SE Mk II 2004 Man. Sal. CDTi 135ps, FBH on red diesel, WinCE6 DD Join Date: May 2010

Location: Leeds

Posts: 17,273

Thanks: 2,160

Thanked 2,061 Times in 1,586 Posts

|

Quote:

__________________

Harry How To's and items I offer for free, or just to cover the cost of my expenses... http://www.the75andztclub.co.uk/foru...40#post1764540 Fix a poor handbrake; DIY ABS diagnostic unit; Loan of the spanner needed to change the CDT belts; free OBD diagnostics +MAF; Correct Bosch MAF cheap; DVB-T install in an ex-hi-line system; DD install with a HK amp; FBH servicing. I've taken a vow of poverty. To annoy me, send money. |

|

|

|

|

|

|

#107 |

|

This is my second home

75 Contemporary SE Mk II 2004 Man. Sal. CDTi 135ps, FBH on red diesel, WinCE6 DD Join Date: May 2010

Location: Leeds

Posts: 17,273

Thanks: 2,160

Thanked 2,061 Times in 1,586 Posts

|

Heating it up would make it easier, but its fairly soft anyway. Just grip the rod in a good tight vice and it will tap down with a hammer quite easily cold.

__________________

Harry How To's and items I offer for free, or just to cover the cost of my expenses... http://www.the75andztclub.co.uk/foru...40#post1764540 Fix a poor handbrake; DIY ABS diagnostic unit; Loan of the spanner needed to change the CDT belts; free OBD diagnostics +MAF; Correct Bosch MAF cheap; DVB-T install in an ex-hi-line system; DD install with a HK amp; FBH servicing. I've taken a vow of poverty. To annoy me, send money. |

|

|

|

|

|

#108 |

|

This is my second home

Rover75 and Mreg Corsa. Join Date: Nov 2006

Location: Sumweer onat mote o'dust (Sagin)

Posts: 21,753

Thanks: 341

Thanked 3,660 Times in 2,924 Posts

|

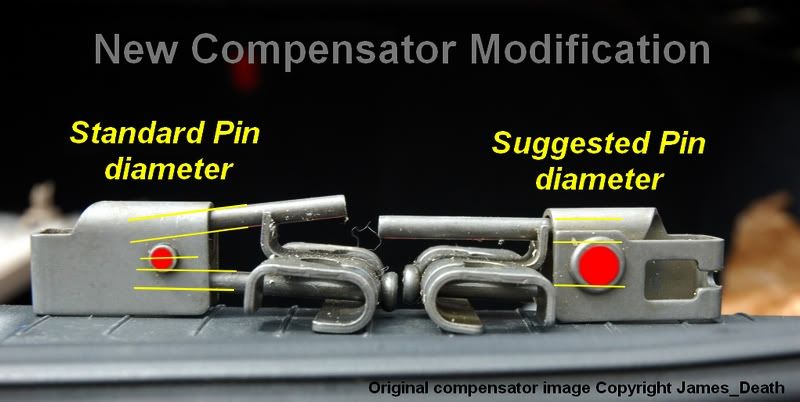

It's a fascinating thread with some great ideas for fixing what is undoubtedly a pretty poor design. Looking at various photos of the new and 'stretched' compensator, it seems clear to me that the root cause of the problem isn't the softness of the U-bar, but the diameter of the rivetted pin that retains it. There's too much slop between the U-bar and the casing. The difference between the diameter of the retaining pin and the ID of the U-bend gives enough leverage for the bend to be pulled along the bar. In theorythe U-bar would eventually pull out of the casing.

It seems to me that maybe an easier solution that doesn't require any welding is to simply replace the pin with one that fits tightly in the U-bar. This would eliminate the leverage around the bend and prevent it creeping. I'm assuming the the bend in the original U-bar is circular, which seems logical but may not be correct (?).  The pin appears to be rivetted into the case, so it could be drilled out, the holes enlarged and a new pin with a more suitable diameter inserted/rivetted. I suppose if you used one of those swivels with a split pin drilling, you could just retain it with a washer and a split pin. I guess the strength of the drilled out case would then be the question. James_Death copyright acknowledged in my drawing. TC |

|

|

|

|

|

#109 |

|

Loves to post

Rover 75 1.8T SE Join Date: Apr 2011

Location: Southport

Posts: 402

Thanks: 1

Thanked 72 Times in 37 Posts

|

I'm not so sure you could do that - I think the whole thing is deliberately designed to be "loose" so any slack caused by slightly different cable lengths, unevenly adjusted/worn shies etc is taken up by the flex - isnt that the whole point of a compensator?

When you think about it if the sole purpose of connecting 2 cables into 1 could be achieved with a rigid plate with 3 holes in it - its got to have flex through a number of planes |

|

|

|

|

|

#110 |

|

This is my second home

Rover75 and Mreg Corsa. Join Date: Nov 2006

Location: Sumweer onat mote o'dust (Sagin)

Posts: 21,753

Thanks: 341

Thanked 3,660 Times in 2,924 Posts

|

As I read it, the compensation is provided mainly by the swivelling/rocking of the hook plate. The upper leg of the U-bar is there to retain the plate so it doesn't turn too much about the lower leg. I think you would prevent creep if the pin was larger diameter without locking the U-bar completely in the case.

The tension on the hook plate is the same as that in the U-bar, but the rolled end doesn't straighten out because there's virtually no sideways moment from the cable barrel. It's the sideways moment in the casing which allows the creep in the U-bar. TC Last edited by T-Cut; 27th July 2011 at 21:02.. |

|

|

|

|

|

|