|

||

|

|

||

|

|

||

|

|

#41 | |

|

This is my second home

Rover 75 Saloon & Tourer Join Date: Sep 2012

Location: Lincoln

Posts: 14,912

Thanks: 1,630

Thanked 3,032 Times in 2,181 Posts

|

Quote:

FWIW, irrespective of manufacturer guidance, unless a very specialist working environment, I would not use a torque wrench to undo nuts and bolts. Those that do, lets agree to disagree  macafee2 |

|

|

|

|

|

|

#42 |

|

I really should get out more.......

MG ZT-T, Rover 75 Tourer Join Date: Mar 2011

Location: Olney

Posts: 2,969

Thanks: 245

Thanked 1,088 Times in 657 Posts

|

How about one of these? https://www.machinemart.co.uk/p/040215238/

|

|

|

|

|

|

#43 | |

|

This is my second home

R75 Saloon. Join Date: Feb 2009

Location: France/or Devon.

Posts: 14,003

Thanks: 3,851

Thanked 2,167 Times in 1,816 Posts

|

Quote:

|

|

|

|

|

|

|

#44 |

|

This is my second home

Rover 75 Saloon & Tourer Join Date: Sep 2012

Location: Lincoln

Posts: 14,912

Thanks: 1,630

Thanked 3,032 Times in 2,181 Posts

|

|

|

|

|

|

|

#45 | |

|

Gets stuck in

MG ZT Join Date: Apr 2018

Location: Bristol

Posts: 695

Thanks: 332

Thanked 164 Times in 133 Posts

|

Quote:

__________________

gnu |

|

|

|

|

|

|

#46 |

|

Gets stuck in

Moonstone diesel,X351 Jaguar and now MG ZT 260 Join Date: Dec 2013

Location: Northampton

Posts: 682

Thanks: 288

Thanked 118 Times in 96 Posts

|

Hi, slightly off topic but still to do with a torque wrench,my old torque wrench snapped its ratchet gear,so I had the ratchet head mechanism welded up and now it makes a perfect breaker bar.Regards Ry......

|

|

|

|

|

|

#47 |

|

Posted a thing or two

Rover 75 Saloon Join Date: Apr 2019

Location: Under the car

Posts: 1,840

Thanks: 210

Thanked 244 Times in 221 Posts

|

LH  RH  The RH nut was a lot tighter than the LH, probably by as much as 20-25%.  Btw, a Silverline 718106 32mm socket will go through the centre of an alloy road wheel, so will a Sealey IS1232 impact socket. The Sealey has less clearance though so it might clatter the wheel if used with an impact wrench. Using the road wheels mean you don't need an assistant on the brake pedal. Thanks to all who posted.   |

|

|

|

|

|

#48 |

|

Give to Learn

Freelander 2 Join Date: Aug 2010

Location: West Midlands

Posts: 18,700

Thanks: 1,155

Thanked 6,407 Times in 3,874 Posts

|

Hi Simon.

What bar did you use in the end, also helps to crack these with the wheel still on the car i find, the rear you have to remove the wheel so you can remove the grease cap. Your next problem but hopefully not in your case, is the little 50 torx on the disc, if you ever change the front discs over, so maybe best to see how tight they are now.

__________________

Arctic Givology Learn to Give Everything is Achievable  ad altiora tendo. Check out our Nano meet dates http://www.midlandsnanomeets.co.uk/ http://www.the75andztclub.co.uk/index.php?thepage=howto " You do the work , we supply the expertise " Last edited by Arctic; 6th July 2020 at 10:37.. |

|

|

|

|

|

#49 | |

|

Posted a thing or two

Rover 75 Saloon Join Date: Apr 2019

Location: Under the car

Posts: 1,840

Thanks: 210

Thanked 244 Times in 221 Posts

|

Quote:

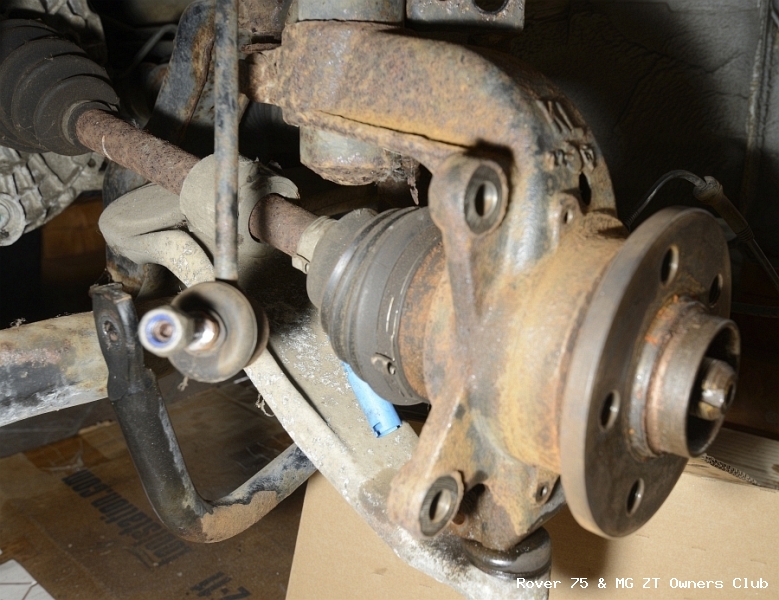

(Thanks for the PM by the way.  ) )I used a 600mm 1/2" bar, extended to 1100mm with the lower half of my trolley jack handle. I was worried the force might oval out the end of the jack handle but it was fine - it did bend the 600mm bar though!  (A 600mm 3/4" bar wouldn't have bent). It was the RH side that did the damage - it was unbelievably tight and I had to jump up and down on the handle/bar to crack the nut. The LH side was far easier and I only had to lean heavily on it a few times. (A 600mm 3/4" bar wouldn't have bent). It was the RH side that did the damage - it was unbelievably tight and I had to jump up and down on the handle/bar to crack the nut. The LH side was far easier and I only had to lean heavily on it a few times.The T50 Torx screws were no problem and the calipers & discs are now off. I'll refurb the calipers and put the new TRW discs on. Next problem is getting the struts off - and the swivel hubs too. Here's the state of play at the moment (LH side shown).  The droplink is disconnected from the ARB, the steering rod is disconnected from the swivel and the pinch bolt for the lower arm ball joint is out (after a struggle!). I might have to read Rave to find out how to separate the swivel from the ball joint and drive shaft, unless someone can tell me the easiest way here.     |

|

|

|

|

|

|

#50 |

|

This is my second home

Rover 75 Saloon & Tourer Join Date: Sep 2012

Location: Lincoln

Posts: 14,912

Thanks: 1,630

Thanked 3,032 Times in 2,181 Posts

|

getting the lower arm out using marinabrians method which I think is the same as rave makes it dead easy.

Get a 4 ft bit of 2x2. wedge one end under the sub frame, tie the lower arm as close as you can get to the ball joint to the 2x2 which should be under the lower arm. Put your weight on the free end of the 2x2, push down if needed. Took me ages to understand the method but once I did, made a difficult task very easy macafee2 not the same as rave, sorry Last edited by macafee2; 6th July 2020 at 20:46.. |

|

|

|

|

|

|