|

||

|

|

||

|

|

||

|

|

#21 | |

|

MG ZT Join Date: Jan 2011

Location: Newcastle Upon Tyne

Posts: 20,151

Thanks: 3,565

Thanked 10,837 Times in 5,718 Posts

|

Quote:

Preload of any threaded fastener is important, as when radial torque is applied what you are actually doing is applying torsional load to the fastener, and placing it in tension. As a rule of thumb, the preload should not exceed 75% of the yield value of the fastener. So when a 10.9 tensile strength cadmium plated bolt, is substituted by a 8.8 bright zinc plated one, the yield value is reduced by 68% of the original fastener, meaning the elastic limits of the fastener are easily exceeded as you have found. In short without delving too deep into semantics, the original fasteners are carefully calculated in design to use the minimum diameter of bolt to effect the correct clamping load to the joint. Substitution without understanding the concept that tension is the important factor, and the applied tension of two otherwise similar components, but of different tensile strength, fastened to an identical torque figure is completely different. Brian  |

|

|

|

|

|

|

#22 |

|

This is my second home

MG ZT-T 190 Monogram Typhoon Join Date: Jan 2009

Location: Oxfordshire

Posts: 4,704

Thanks: 328

Thanked 557 Times in 443 Posts

|

Hi Brian.

I'm annoyed at myself. I work in engineering and saw the bolts were marked up 8.8. I should have stopped the job.  |

|

|

|

|

|

#23 | |

|

Give to Learn

Freelander 2 Join Date: Aug 2010

Location: West Midlands

Posts: 18,699

Thanks: 1,155

Thanked 6,407 Times in 3,874 Posts

|

Quote:

You are allowed to be  with yourself we all make little mistakes now and then, what comes after is how you learn from them with yourself we all make little mistakes now and then, what comes after is how you learn from them  lets hope DMGRS will now remove these from sale with the arms and either add the correct ones or point purchaser in the right direction from where they can be sourced, hopefully you will be able to remove the snapped bolt without to much trouble. lets hope DMGRS will now remove these from sale with the arms and either add the correct ones or point purchaser in the right direction from where they can be sourced, hopefully you will be able to remove the snapped bolt without to much trouble.

__________________

Arctic Givology Learn to Give Everything is Achievable  ad altiora tendo. Check out our Nano meet dates http://www.midlandsnanomeets.co.uk/ http://www.the75andztclub.co.uk/index.php?thepage=howto " You do the work , we supply the expertise " |

|

|

|

|

|

|

#24 |

|

Premium Trader

Rover 75 Join Date: Nov 2010

Location: Devon

Posts: 33,764

Thanks: 8,837

Thanked 14,831 Times in 8,030 Posts

|

With a new bolt this should hopefully be an easy task, once the pressure is off the bolt (As it will be when it has snapped) The threaded part shouldn't have too much resistance.

__________________

Lest we forget..

|

|

|

|

|

|

#25 | |

|

This is my second home

MG ZT-T 190 Monogram Typhoon Join Date: Jan 2009

Location: Oxfordshire

Posts: 4,704

Thanks: 328

Thanked 557 Times in 443 Posts

|

Quote:

I'll sort it, not impossible just much more work than it was supposed to be, and it's my Dad who is without a car for a few more days. DMGR's have acknowledged so they're are on it. This need sorting out for their sake as well, as a failure at another time could have much more severe consequences. |

|

|

|

|

|

|

#26 |

|

This is my second home

Rover 75 Saloon & Tourer Join Date: Sep 2012

Location: Lincoln

Posts: 14,912

Thanks: 1,630

Thanked 3,032 Times in 2,181 Posts

|

may be quicker to remove sub frame and do it on the floor

macafee2 |

|

|

|

|

|

#27 | |

|

Premium Trader

Rover 75 Join Date: Nov 2010

Location: Devon

Posts: 33,764

Thanks: 8,837

Thanked 14,831 Times in 8,030 Posts

|

Quote:

I would try and see if you can get a punch or a small chisel on the broken bolt to see if you can turn it enough to allow a small pair of long nosed pliers in.. Good luck.

__________________

Lest we forget..

|

|

|

|

|

|

|

#28 |

|

This is my second home

MG ZT CDTi Join Date: Jan 2014

Location: carrick

Posts: 7,859

Thanks: 3,494

Thanked 2,657 Times in 1,973 Posts

|

would a screw extractor work? I imagine it would on the floor, I cannot remember how much space there is fitted

__________________

It is not gloss primer .............. it is duct tape silver! |

|

|

|

|

|

#29 |

|

Gets stuck in

Maintainer of sons ZT M47r Join Date: Dec 2013

Location: Shropshire

Posts: 624

Thanks: 609

Thanked 124 Times in 100 Posts

|

I had the same thing a few years ago with DMGRS and told him about it. Not only are they the wrong property grade, they have insufficient corrosion protection too. I would not sleep at night supplying inferior replacements for safety critical parts. It would seem a little knowledge could be dangerous.

|

|

|

|

|

|

#30 |

|

Posted a thing or two

Rover 75 Saloon Join Date: Apr 2019

Location: Under the car

Posts: 1,840

Thanks: 210

Thanked 244 Times in 221 Posts

|

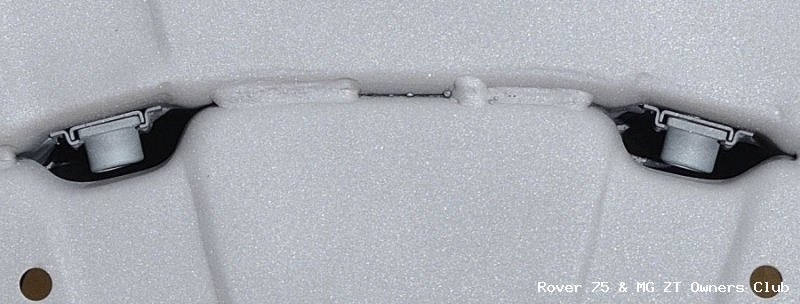

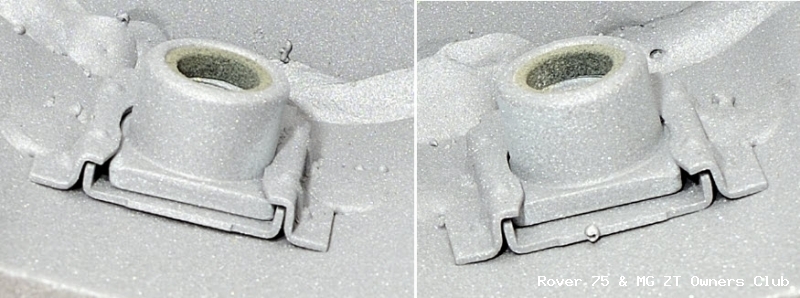

Ben - here's a pic in case it helps.

1. Captive nuts as viewed from above the subframe.  2. Blow up of above (split)  3. Clearer view of the captive nut cage (lower arm shown)  4. Above taken from this wide shot (lower arm again)  |

|

|

|

|

|

|